Metal spraying procedures – thermal spraying

During metal spraying the melted spray additives are mostly sprayed by using compressed air, but also other spraying gases or gas flow from the heat source. The parts meet the substrate surface with a very high kinetic energy, they are deformed and the material to be sprayed is quickly cooled down on the relatively cold substrate. This results in a layer made of metal, oxides and very small intermediate spaces.

Advantages of thermal spraying

- Almost any material can be coated/sprayed

- The metal to be coated is not thermally changed

- Almost any component size (independent of the basic material) can be coated

- Excellent automation of the thermal spraying process

- Flexible operation

- High dimension accuracy

- High quality standard

- Several elements are contained within the spraying layer and can be combined (e.g. Cr, Ni, carbides etc.)

DNV GL-Certification

DMI Drechsler is certified in metal spraying of piston rods by DNV GL.

Our procdures

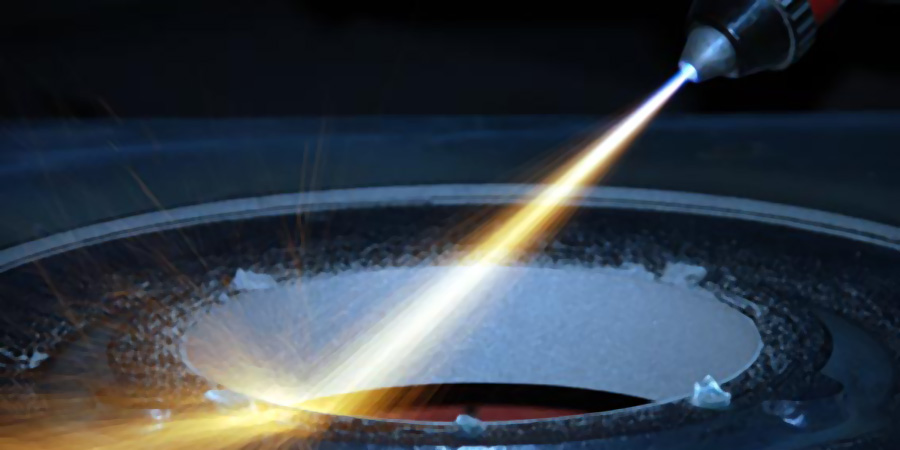

The wire or rod-shaped spraying additive is continually melted in a fuel gas-oxygen flame and hurled onto the work piece surface by using only the fuel gas resp. with the additional help of spraying gas, such as compressed air or nitrogen. When it impinges and solidifies, mechanical anchoring and diffusion zones are developed.

During powder flame spraying the continuously added powder-like spraying additive is pre-melted and melted in an acetylene-oxygen flame. It is sprayed onto the prepared work piece surface, accelerated by the expanded fuel gases.

This method is applied e.g. for chemical resistance sockets, roller table rolls, bearing seats, ventilators, rotors of extruder screws etc.

During arc spraying two wire-shaped spraying additives of the same or different type are melted within an arc. The arc burns solidly between the two wires which are polarised as anode and cathode. The melted metal particles are hurled onto the prepared work piece surface at approx. 120 m/s by using spraying gas. This method is applied e.g. for extensive coating of components, wear and corrosion protection etc.

At DMI Drechsler this procedure is also used for wear-resistant coating of piston rods.

During high-speed flame spraying the gas is continuously burned at a high pressure within a combustion chamber. The powder-type spraying additive is axially or radially added to the central axis of this combustion chamber. Due to the pressure of the fuel gas-oxygen mixture created within the combustion chamber, a high flow velocity of more than 750 m/s (supersonic) is developed within the gas jet. With this procedure we achieve extremely thin layers with high dimension accuracy.

This method is applied e.g. for sliding surfaces, hydraulic rods, rollers, parts for petrochemical and chemical machines, e.g. pumps, slides, ball valves, mechanical seals, valve stems etc.